Fusing Technics’ traditional analogue and leading-edge digital technologies

Launched in 2016, the SL-1200G combined Technics‘ traditional analogue technology and advanced digital technology, while redesigning parts throughout. Its outstanding performance literally rocked the hi-fi market and redefined the reference for direct-drive turntables. Parts that were inherited from the SL-1200G were newly developed for the SL-1200GR, beginning with the coreless direct-drive motor and precise motor control technology that eliminated the cogging that originated from rotation irregularity, and including a low-vibration, high-rigidity platter and high-sensitivity tonearm. By these measures, the level of performance clearly outperforms the usual standards of its class. The SL-1200GR invites more audio enthusiasts to enjoy music with the rich, robust sound of analogue records.

Coreless Direct-Drive Motor Achieving Stable Rotation

In 1970, Technics commercialized the world‘s first direct-drive turntable, and the system took the world by storm. Unlike belt-drive and other systems, direct-drive systems rotate the motor at low speed and directly drive the platter, thus providing numerous advantages, such as the almost complete absence of degradation in S/N ratio due to motor vibration and deceleration mechanisms, as well as high reliability over a long period time because of not requiring parts replacement.

And in 2016, Technics developed the twin-rotor, surface-facing, coreless direct-drive motor with rotor magnets placed on both sides, thereby eliminating the rotation irregularity of the motor, referred to as “cogging,” which was a unique issue for direct-drive systems. This motor was adopted for the SL-1200G, which once again drew a significant response in the hi-fi market. The SL-1200GR inherits the same design philosophy with the new development of a single-rotor, surface-facing, coreless direct-drive motor, resulting in the elimination of cogging.

High-precision Motor Control for Ideal Rotation Conditions

The rotation control, which verifies and corrects the precision of the motor, uses the latest motor control technology cultivated in the development of Blu-ray disc devices, just as that used by the SL-1200G. Sine waves stored in ROM are used for the control waveforms at constant speed, and this achieves smoother and more stable rotation compared with using the simple sine wave generation with an external coil as in the conventional SL-1200MK5. In addition, the electrical circuitry has had tuning performed so that the newly developed motor of the SL-1200GR achieves maximum performance. The starting torque achieves 2.2 kg x cm with only a single rotor. The same startup time of 0.7 s (at 33 1/3 rpm) as the SL-1200G has been achieved.

Pursuing Rigidity and Vibration Damping Characteristics

The platter achieves high rigidity and vibration damping characteristics by using a two-layer construction with deadening rubber applied to the entire rear surface of the aluminium die-cast to eliminate the unnecessary resonance that is otherwise relayed to the record, thereby producing clear sound.

To increase the inertial mass and reduce vibration, the shape of the aluminium die-cast portion was optimized by simulation. At 2.5 kg (including the rubber mat), the SL-1200GR platter is 0.8 kg heavier than that of the previous SL-1200MK5. Also, the back surface of the platter has strengthening ribs added to improve rigidity. Increasing the surface area of contact with the deadening rubber achieves damping characteristics that are more than twice those of the SL-1200MK5.

Tonearm Achieving High Initial-Motion Sensitivity

The tonearm tracks the rotation of the record and enables reading with high precision, and the tonearm inherited by Technics is the traditionally used static-balance universal S-shaped tonearm, employing an aluminium pipe with excellent light weight and rigidity for the material of the tonearm pipe.

With its gimbal suspension construction, the tonearm bearing section uses a cut-processed housing that employs high-precision bearings, as in the SL-1200G. The high initial-motion sensitivity of 5 mg or less is achieved through manual assembly and adjustment by skilled Japanese artisans. This enables the grooves etched into the records to be accurately traced.

In addition, one type of auxiliary weight comes included, and the cartridge can be swapped with a variety of other cartridges to match the music genre or feeling. (Applicable cartridge weight when using the supplied auxiliary weight: 10 – 16.4 g (not including the supplied head shell))

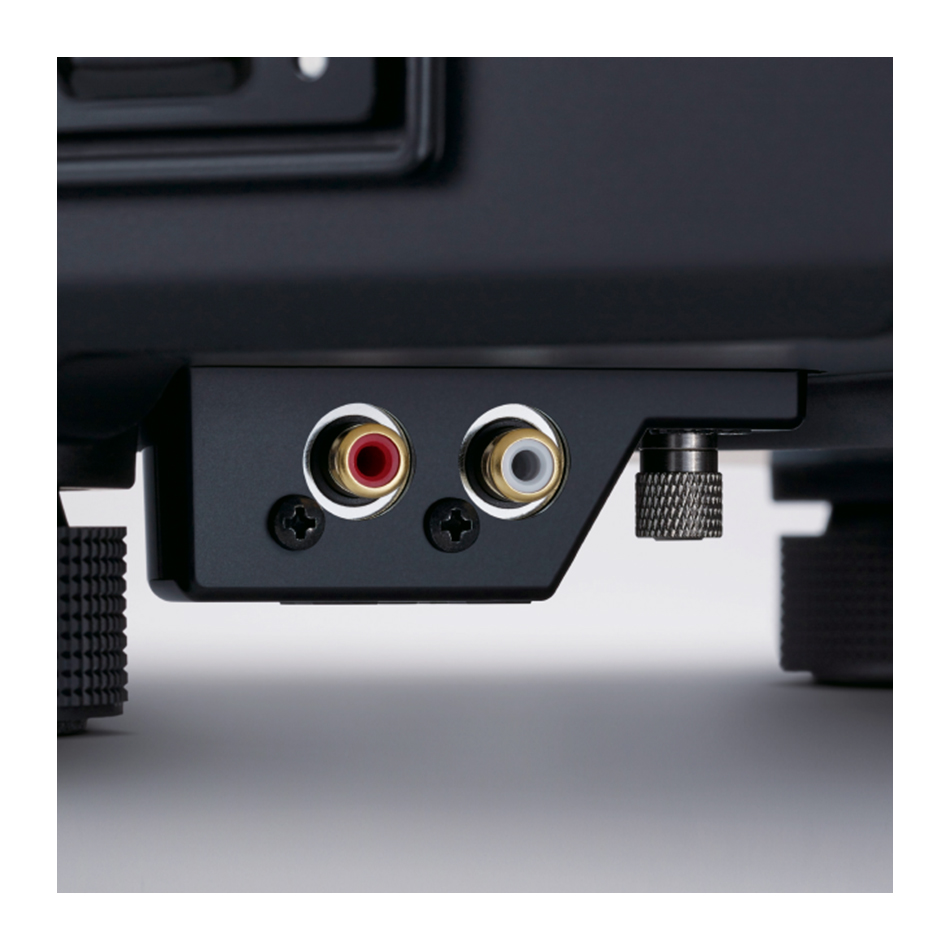

High-quality Terminals for Both Sound and Appearance

The turntable uses gold-plated phono terminals for detachable cables, and so a wide variety of cables can be selected. Also, the use of metal shielding construction inside the case reduces the effects of external noise.

High-rigidity Body and High-damping Silicon Insulators for Smooth Sound and Isolation from Various Vibrations

The SL-1200GR ensures high rigidity by using a body with a two-layered construction solidly unifying the BMC and the aluminium die-cast chassis. For the insulators supporting the body, as with the SL-1200G, the SL-1200GR uses special silicon rubber that ensures both high vibration damping characteristics and long-term reliability. Vibration in the horizontal direction is absorbed by reinforcement with cylindrical tubes using microcell polymers. While inheriting the technology of the SL-1200G, the insulators have had tuning performed specifically for the SL-1200GR.

Also, the installation section of the insulators is equipped with a vertical adjustment mechanism using screws. This eliminates the rattle that occurs when the turntable is installed in a rack or the like, and prevents unwanted vibration. In addition, exact horizontal adjustment of the platter and record surface reduces rotation irregularity due to slanting, thereby enabling more stable record playing.

Sharath –

Best direct drive turntable in the world ever made.