New tonearm with knife edge bearing

The PD-151 MARK II has been newly equipped with LUXMAN’s original static balance type tone arm, the LTA-309, featuring knife edge bearing technology developed by the Japanese brand SAEC, with over 40 years of experience. The arm base is machined aluminum, which minimizes the contact area, mounted to suppress unwanted vibration while ensuring rigidity. In addition to basic adjustment mechanisms, such as stylus pressure and anti-skating, LTA-309 also supports fine settings to optimize playback quality, such as arm height adjustment, according to the mounted cartridge. This S-shaped tonearm employs an H4 bayonet mount headshell, allowing easy install of phono cartridges, such as the LUXMAN LMC-5.

New High precision/ High torque proprietary DC motor

The purity of musical pitch depends entirely on the stability of platter rotation. That’s why LUXMAN engineers went to extraordinary lengths. We start with our unique sine wave/Pulse Width Modulation power supply, which provides ultra-stable direct current to our proprietary DC brushless motor. Years in development, this low-speed high-torque motor incorporates low-acoustic noise bearings and internal construction. The drive system monitors and maintains speed with our Proportional-Integral-Differential (PID) feedback control loop. Proportional means quick achievement of target speed. Integral means fast correction of minor errors. And differential means control over rapid fluctuations. For added precision, the motor drives the outside flange of the platter through an uncommonly wide belt for stabile 33 , 45 and 78RPM playback speeds with +/-6% manual pitch control adjustment available.

High-Mass platter and highly rigid stainless-steel spindle

LUXMAN engineers were determined to optimize the final guarantor of stable speed; the platter assembly itself. PD-151 MARK II has a 4.0kg platter precision machined from a thick aluminum billet then diamond-cut finished to exact surfaces. The platter acts as a flywheel, with a large moment of inertia (0.219t·cm2 ) to insure smooth and stable rotation. The spindle supporting the platter is a highly rigid, 16mm diameter, hard stainless-steel shaft with bearings at the lower end. It comfortably supports the platter weight with a bearing structure that combines a thrust bearing lubricated with PEEK* material, with excellent heat and wear resistance, and a brass radial bearing filled with organic molybdenum oil that maintains excellent lubricity under high load. A turntable mat of special vibration-absorbing rubber material is included to support vinyl records during playback.

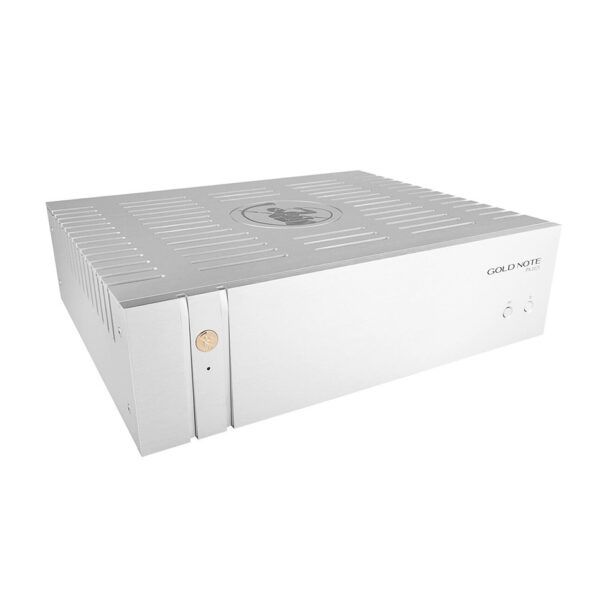

LUXMAN exterior design pursuing functional beauty

PD-151 MARK II inherits the highly praised LUXMAN exterior design and operational layout of our previous model PD-151. The top panel, made from 10mm thick aluminum with its delicate hairline finish, pursues simplicity and functional beauty with a component layout narrowed down to only the three major analog player elements; the tone arm, drive motor and platter. The operational controls, such as power switch, motor (rotation) ON/OFF switch, rotation speed changeover switch, indicators, etc. are all integrated into PD-151 MARK II front panel. While achieving both highly intuitive operability and visibility, the exquisite aluminum top panel combines with the matte black lower housing to create profound visual contrast. Sold separately is an available and highly recommended, purpose built 4mm thick acrylic dust cover, equipped with cam/spring supporting hinges for easy opening and smooth closure.

LUXMAN 3-step rotation speed switching with independent adjustment functions

The PD-151 MARK II supports three rotation speeds: 33 1/3, 45 and 78 rpm. With the whole system prepared independently for each rotation speed, it is possible to make fine and accurate adjustments while observing the rotation speed deviation indicator (LED)*.

Internal damping material

In order to accurately detect and reproduce an extremely low-level analog audio signal and deliver the output to an amplifier without deterioration, it is necessary to thoroughly suppress unwanted vibrations. Inside the PD-151 MARK II the drive motor and power transformer, which are often sources of such vibrations, are mounted with special damping rubber to prevent interference with high quality audio signals.

Unique underslung structure

The PD-151 MARK II has succeeded in achieving both rigidity and vibration damping by attaching heavy components to the underside of the 10mm thick aluminum top panel using our original damped underslung hanging method. We have adopted a framework structure that controls small vibrations within a box-shaped chassis on the underside, the crosspiece being the top panel.

Height adjustable damping insulators

The insulator feet that support the entire structure are vital to an analog player while tracking the minute grooves pressed into a phonograph record. The PD-151 MARK II incorporates vibration damping rubber with excellent temperature characteristics into our originally designed insulator feet, with up to 5mm independent height adjustment, which prevent feedback and external vibration transmission.

Headshell and phono signal cables

A lightweight, original machined aluminum headshell with the LUXMAN logo and an aluminum EP adapter are included as standard. To accept the phono cartridge output, we have adopted audio grade OFC wiring into the high quality, highly versatile DIN-RCA phono cables. Future upgrades are also possible.

AC inlet and power cable

The AC inlet’s structure has been improved to support the weight of heavy power cables by reversing the mounting, suppressing any movement of the power cable while maintaining a stable grip.

Reviews

There are no reviews yet.