Cleaning

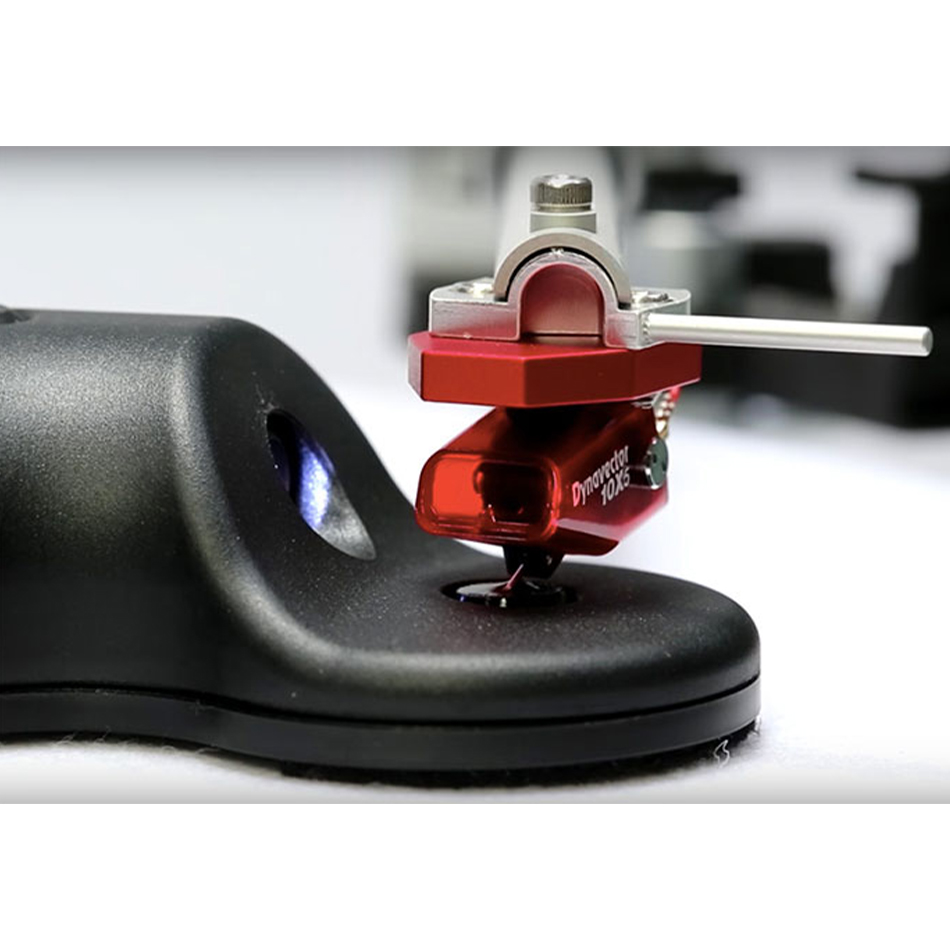

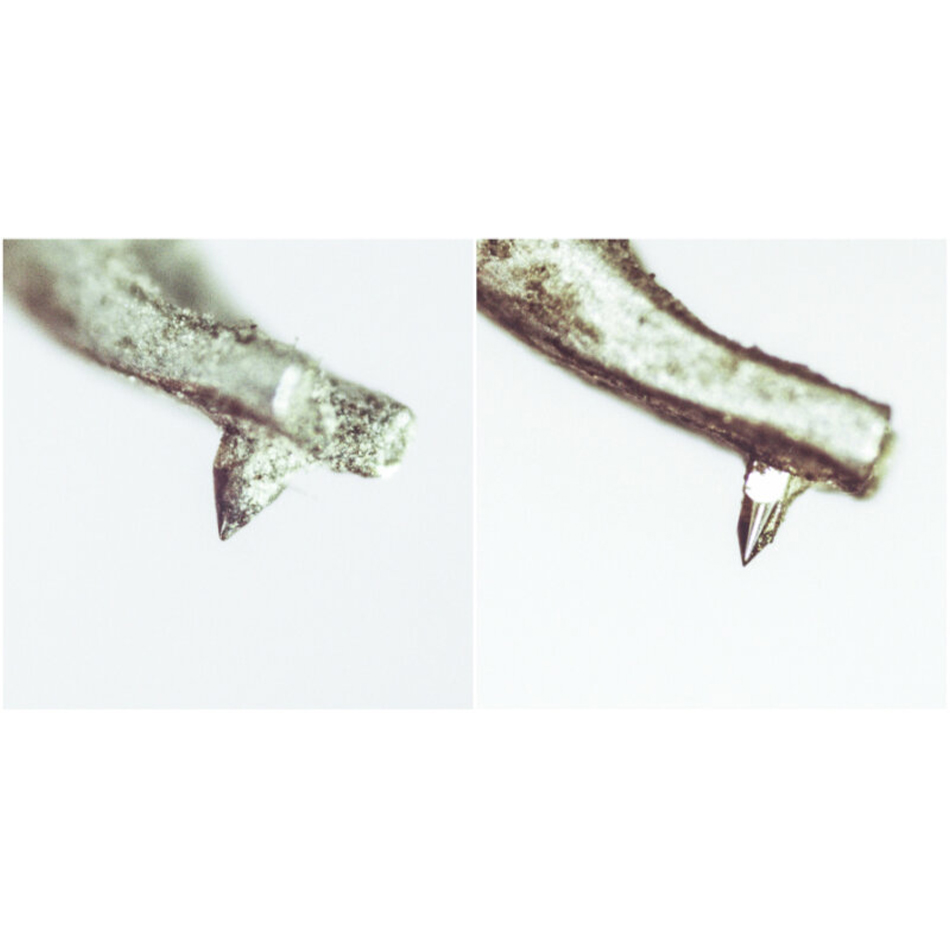

The stylus is the primary component in the playback process. The motion, which will later induce voltage, is created here. The aim is to accurately track the groove in the micrometer range. The manufacturers of pickups undertake substantial efforts to achieve this goal perfectly. However, if the needle is dirty, the diamond – no matter how ground and polished it is – cannot exactly follow the deflection. It reacts too early or too late, and this leads to distortions. Even supposedly clean records are covered with dust, partly visible, partly invisible in the groove. This includes particles of silicates, polymers and organic materials. These adhere to the needle during the scanning process, due to the high temperature. This happens very quickly, after playing one record side, the needle is hardly visible due to dirt.

Technique

The operating principle is similar to an ultrasonic cleaner used in dental technology or an ultrasonic bath for eyeglasses. The surface is cleaned using strong high-frequency vibration. The treatment with ultrasound causes damage in some materials, such as aluminum. Even if the diamond would be perfectly cleaned, the adhesive joints and the suspension of the needle carrier would be harmed, same as with the application of aggressive cleaning liquids. The Flux-Sonic vibration cleaner, however, operates at a low frequency. The circuitry and mechanics are designed so that a three-dimensional vibration acts on the needle, ensuring that all dirt particles are removed. The frequency is exactly tuned so that damage to the bonding or the suspension is ruled out – the cleaning result, however, is perfect. The deflections are far from the values of the actual scanning. The motion of the needle corresponds only to a fraction of the load during the playback process. A fluid is needed to transmit vibrations from the device to the needle. This fluid, prepared on the basis of isopropanol, ensures an additional, gentle cleansing effect. After its application, it evaporates without leaving a residue. Flux-Fluid is applied on a specially designed pad made of the finest PE fibers. Due to their number and the resulting density, these fibers already produce a capillary effect, which is very similar to the effect of a liquid. In conjunction with Flux-Fluid, we get a perfect combination that transmits the vibration and, at the same time, absorbs the dirt. We recommend using it every time before playing a record.

Result

The cleaning process takes just 15 seconds to reach the optimum. The scanning capability of the pickup system is improved. The service life of the needle increases due to less abrasion. Scanning noise is significantly reduced. In terms of sound quality, the difference is outstanding. Both distortions and disturbing interference have largely disappeared. The playback has become much more dynamic and enjoyable. Unpleasant peaks are no longer present and even large modulations are reproduced without distortion. The frequency range appears expanded, especially in the bass and treble range. Of course, the cleaning of the record is just as important as the cleaning of the needle. Please keep your records as clean as possible. A device by Flux-Hifi is already in development.

Reviews

There are no reviews yet.